Knowing When to Replace Your Forklift

There are more than 1 million forklifts on operations across North America. Of these 1 million lift trucks, nearly 50% of them are negatively impacting the bottom line of their operation. The primary cause for this concerning number is that operations tend to use forklifts well beyond their expected lifespan.

To ensure your fleet isn’t hurting your budget, you need to know what each forklift’s ownership and maintenance costs are. These costs can be determined by referencing PM records, inspection reports, and your hour meter.

First, you need to determine your ownership cost for each unit. This is the difference between the delivered cost and its residual value when traded in. For an example, let’s say that a forklift costs $15,000, is four years old, and has 8,500 hours on it. These stats result in a trade-in value of $6,000. Now, subtract this value from the delivered cost ($15,000) to get the ownership cost. This results in a total ownership cost of $9,000. Finally, divide this cost by the total engine hours (8,500). By following these steps, you’ll see that your forklift costs roughly $1.06/hour to run.

Next, you’ll want to determine your cumulative maintenance costs. This amount is calculated from the cost of maintenance and parts from the date of purchase. Using the forklift from the example above, let’s say it has maintenance costs of $8,800 over four years. You’ll want to divide this amount by the total engine hours (8,500) to determine your maintenance costs. The result is $1.04/hour to maintain your forklift.

Now, add these costs together. In the example above, the forklift costs $2.10/hour to operate. Knowing how much you spend on hourly operation is crucial for budgeting. This cost will also inform you when it’s time to replace your existing forklifts with newer models. Most operations tend to simply replace their forklifts once they reach a certain age. This varies greatly by application, but it typically ranges from 3 to 7 years.

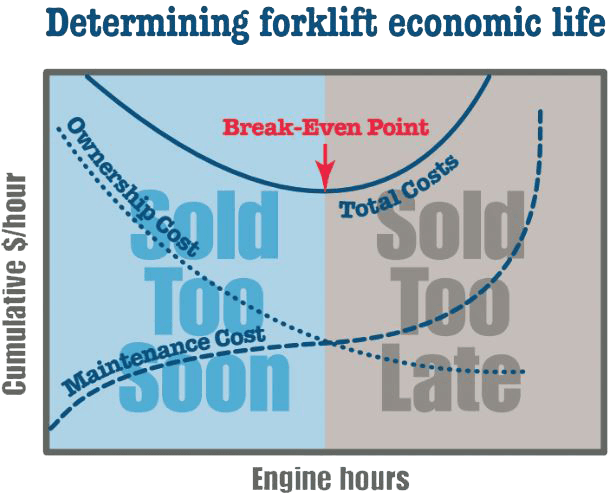

As you may expect, this policy is rarely ideal for maximizing value and return on investment. Sticking to a set time period may result in you replacing units too early or too late. Both of these scenarios result in lost value. An accurate performance profile based on detailed records is the best way to determine the correct replacement point.

The most cost-effective time to replace a forklift is at its lowest total cost point. This is also known as the economic break-even point. Maintenance costs will rise after this point has passed. You may end up spending more than necessary to keep that forklift in operation as a result. It should be noted that this doesn’t include lost productivity or the cost of downtime during repairs. This means that you may be losing even more revenue than just service costs. See the chart below for a visual reference of a forklift’s economic lifespan.

By understanding your operating costs, you’re able to determine the best time to replace your forklift. This ensures that you’re always using quality equipment for the job without damaging your bottom line. If you’re wanting to save the hassle of tracking these costs yourself, consider one of our fleet management programs. When enrolled in one of these programs, we monitor your fleet for you to determine optimal turnover times. Depending on the program you choose, we also handle maintenance and repairs. This ensures that your equipment is always in good working order, keeping downtime to a minimum. Contact Lonestar Forklift today to learn more about our fleet management options!