-

Beyond Forklifts: Exploring Specialized Material Handling Equipment

Updated: Oct 11, 2024Beyond forklifts, there's a vast array of specialized material handling equipment designed to meet unique challenges. From telehandlers and order pickers to AGVs, each type enhances efficiency and safety in various industries. At Lonestar Forklift, we offer a diverse range of equipment to optimize your operations. Discover how the right tools can elevate your business, whether you're managing high racking systems, rough terrain, or automated workflows. Let's lift Texas together! #letslifttexasFull story -

Boost Your Bottom Line: How Section 179 Can Save You Big in 2024

Updated: Aug 8, 2024Maximize tax savings in 2024 with Section 179 at Lonestar Forklift Inc. Deduct up to $1,160,000 of new or used equipment purchases and take advantage of 80% bonus depreciation. Improve cash flow, upgrade to advanced, energy-efficient forklifts, and support business growth.Full story -

Elevating Texas Projects: The Manitou Skid Steer Advantage

Updated: Aug 21, 2024For Texas ranchers, landscapers, and construction outfits looking for a dependable, powerful, and economical skid steer, Manitou provides a premier choice. The Manitou skid steer isn’t just a piece of machinery; it’s a critical asset for enhancing operational capacity and achieving project success across various industries in Texas.Full story -

Increasing ROI: How Material Handling Equipment Can Improve Business Bottom Lines

Updated: Jun 21, 2024In the rapidly evolving sectors of logistics and manufacturing, achieving efficiency and reducing costs are not just goals—they are necessities for staying competitive. At Lonestar Forklift, we understand the critical role that advanced material handling equipment plays in enhancing operations and boosting return on investment (ROI). Innovations by industry leaders such as Hyundai, Manitou, and Konecranes have revolutionized this field, offering solutions that streamline operations and significantly enhance financial returns.Full story -

Sustainable Solutions: Eco-Friendly Material Handling Practices

Updated: May 22, 2024Explore the future of material handling with Lonestar Forklift, where our electric equipment offers substantial environmental and economic advantages. See how our electric forklifts are transforming industries by reducing emissions, lowering energy costs, and improving operational efficiencies. Join us in driving sustainability and innovation in material handling.Full story -

Building Success: Material Handling Innovations for the Construction Industry

Updated: Apr 26, 2024The innovations in material handling technology are reshaping the construction industry, offering new opportunities for efficiency and safety. At Lonestar Forklift, we are committed to providing our customers with access to the latest advancements from leading brands like Manitou, JLG, and Genie. Whether you're looking to improve your project's efficiency or enhance safety on your construction site, our team of experts is here to guide you through the best solutions tailored to your needs. Visit us at one of our Lonestar Forklift locations, and let's build success together with the next generation of material handling innovations.Full story -

Smooth Sailing: Enhancing Material Handling in Ports and Intermodal Terminals

Updated: Mar 29, 2024Discover how Tico yard spotters, KoneCranes container handlers, and Carer high capacity forklifts revolutionize port operations, enhancing efficiency, safety, and sustainability in the demanding world of global trade and logistics.Full story -

Exciting News: Permian Machinery Movers Joins Lonestar Forklift

Updated: Apr 8, 2024Lonestar Forklift is thrilled to announce the acquisition of Permian Machinery Movers, marking a new chapter of growth and expansion. This strategic move enhances our service offerings and extends our reach into west Texas. By combining strengths, we're set to offer more options and solutions to our customers, ensuring a smooth transition with co-branding efforts leading to a united future under the Lonestar Forklift brand.Full story -

From Forest to Factory: Elevating Lumber Material Handling in Texas

Updated: Mar 20, 2024In Texas, the lumber industry is revolutionizing with advanced material handling from Hyundai, Carer, & Konecranes. Mobile equipment enhances efficiency, safety, and sustainability, ensuring a brighter future for the sector.Full story -

Choosing the Right Forklift: Maximizing Your Material Handling Equipment Investment

Updated: Dec 13, 2023Choosing the right forklift is about maximizing your material handling equipment investment. Lonestar Forklift is committed to helping you choose the right equipment for your needs, for peak efficiency, safety, and productivity. Reach out to us today.Full story -

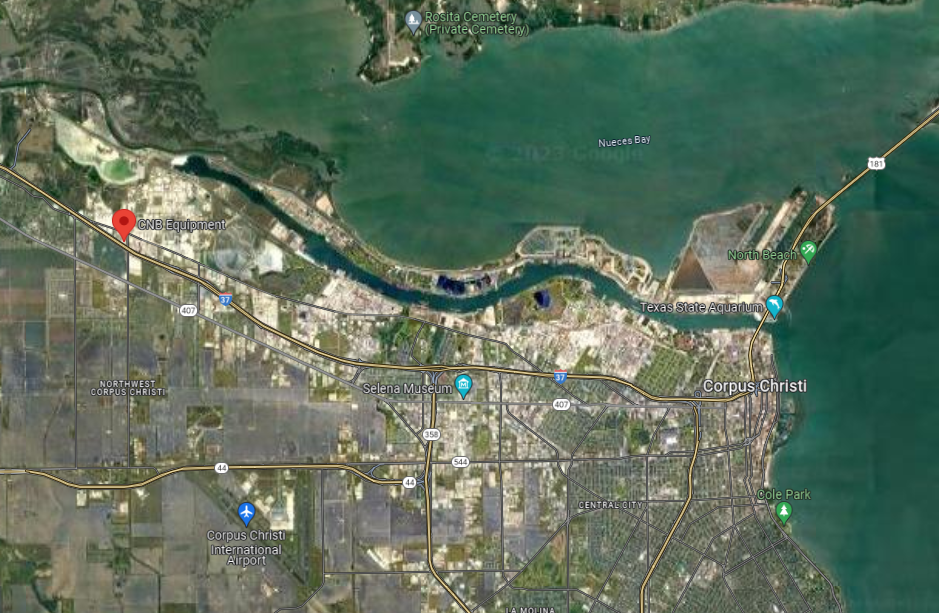

CNB Equipment | Now The Corpus Christi Branch of Lonestar Forklift.

Updated: Dec 13, 2023We are pleased to share that CNB Equipment (“CNB”) has been acquired by Lonestar Forklift. CNB Equipment has been providing materials handling equipment sales, rentals, parts, and support since 2009, serving customers from its facility in Corpus Christi.Full story -

The Service Advantage: Why Regular Maintenance is Vital for Material Handling Equipment

Updated: Oct 25, 2023Regular maintenance is vital for material handling equipment for several reasons. The Service Advantage, as it is often referred to, encompasses a range of benefits that ensure the smooth and efficient operation of these essential machines. Here are some key reasons why regular maintenance is crucial:Full story -

10 Tips For Forklift Operators This Fall

Updated: Mar 20, 2024Forklift safety in fall: Check forklift, use lights, avoid slippery surfaces, mind wind, dress appropriately, secure loads, watch weather, keep distance, navigate rough terrain carefully, and update training.Full story -

Powering the Energy Sector: Optimal Material Handling in Oil & Gas Operations

Updated: Sep 29, 2023Optimal material handling in oil and gas operations is crucial for ensuring the efficient and safe extraction, processing, and transportation of hydrocarbons. Material handling encompasses various activities involved in moving, storing, and controlling materials and equipment used in the industry. From drilling rigs to refineries and distribution facilities, effective material handling can significantly improve productivity, reduce downtime, and enhance overall safety.Full story -

Supercharge Your Fleet Upgrades: Slash Taxes with Section 179

Updated: Dec 19, 2023Decrease taxable income & upgrade your fleet. The IRS revisions to Section 179 that allows up to 100% deduction of the total cost of any new or used equipment bought and put in serviceprior to Dec 31 2023.Full story -

Overcoming Material Handling Challenges in the Pipe and Concrete Industries

Updated: Aug 21, 2023The Pipe and Concrete industries face diverse material handling challenges, from handling various materials to addressing specialized project requirements. Lonestar Forklifts is dedicated to empowering these industries with top-quality material handling equipment and exceptional expertise. By partnering with Lonestar, businesses gain access to a comprehensive range of equipment options, tailored solutions, and unwavering support. With Lonestar Forklifts by their side, the Pipe and Concrete industries can confidently tackle any material handling challenge and thrive in the ever-evolving construction landscape.Full story -

Unlocking Operator Success: Konecranes' Lift Trucks and Reach Stackers - A Key to Productivity and Job Satisfaction.

Updated: Aug 1, 2023At Lonestar Forklift dealerships, we are proud to be your trusted Konecranes dealer, offering industry-leading lift trucks and reach stackers. Konecranes' commitment to operator comfort, safety, and efficiency is unmatched.Full story -

Beat The Heat, Cool Advancements In Operator Comfort.

Updated: Jun 30, 2023Hyundai's construction and material handling equipment, with their focus on comfort and safety, provide a reliable solution to enhance productivity, reduce health concerns, and ensure a positive working experience. By investing in Hyundai's operator comforts, employers can create a conducive work environment that prioritizes employee satisfaction, productivity, and long-term success.Full story -

TURNOVER IS EXPENSIVE. KEEP YOUR EMPLOYEES.

Updated: Jun 14, 2023Employee comfort is a crucial factor in employee retention, and Manitou is recognizing this by incorporating ergonomic designs and technology into their equipment. By prioritizing operator comfort and safety, manufacturers like Manitou are giving companies the opportunity to provide a work environment that is supportive and comfortable, leading to increased employee satisfaction and retention. Employers who invest in their employees’ comfort are likely to see long-term benefits in terms of increased productivityFull story -