5 Winter Forklift Safety Tips

Winter is a difficult season to navigate and can cause serious harm to your equipment if you’re not careful. The cold and wet weather can cause serious equipment damage if you aren’t careful. We want to help you protect your greatest assets. That’s why we’ve put together our top 5 winter forklift safety tips to help get you through the coming months. Making sure that you are properly starting your equipment is the most important thing you can do in the colder months. Block heaters, battery blankets, hydraulic tank heaters, and oil pan heaters are all helpful, but unfortunately, they are not enough to prevent breakdowns in colder climates.

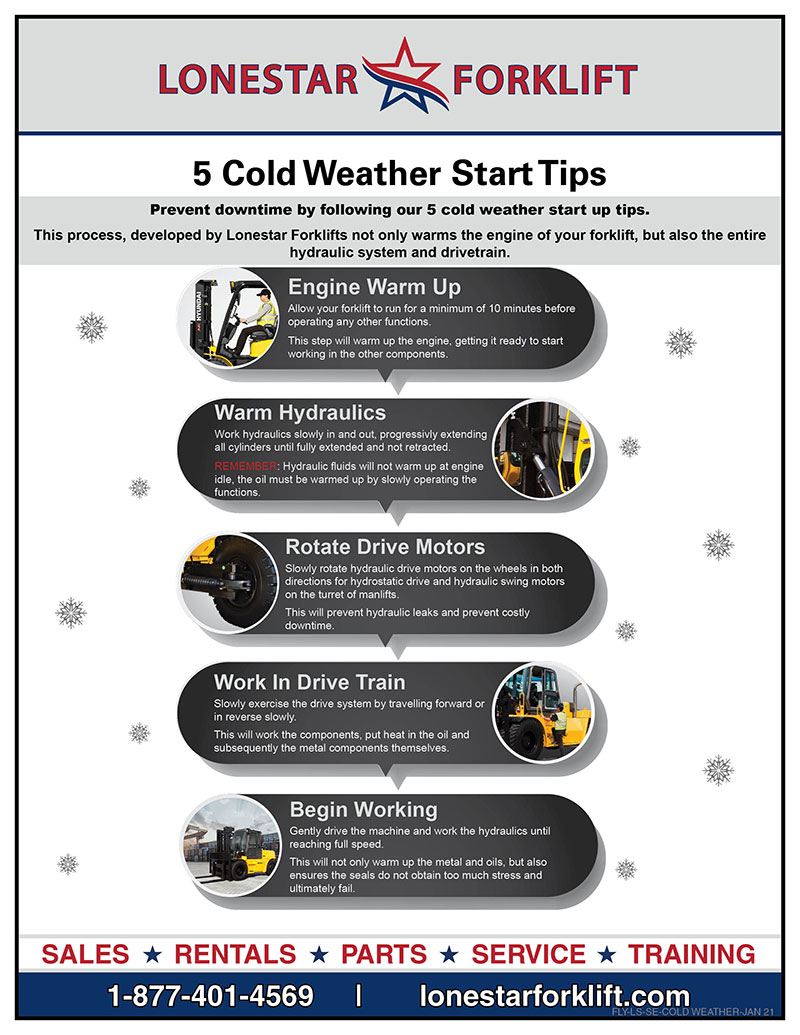

Keep reading below to learn about our 5-step process to warm your engine, the entire hydraulic system, as well as the drive train. Each step will walk you through how to warm up the important components of your equipment, and why it’s so important. Following these steps will help you avoid costly downtime and keep your equipment up and running all winter long! If you get all the way to the end, there is also a helpful printout at the bottom of this blog. You can post the infographic in your service shop, equipment yards, or break rooms to act as a helpful reminder for your team.

Run your equipment for 10 minutes before operating any other functions

Running your equipment for at least 10 minutes will help to warm up the engine and get it ready to start working with the other components of your machine. Some may think this is a waste of time, but you can use the time to accomplish other small tasks. Use your extra 10 minutes to do your walk-around inspection, or tidy something in your yard!

Take it slow with warming up your hydraulics

It’s best to work slow with the hydraulics, moving them in and out to start. Make sure you stroke all cylinders further and further until they have been extended and retracted. Don’t forget to do this step with all functions of the machine, including auxiliary functions. Hydraulic fluids do not warm up when the engine is idling. The oil gets warm by performing operating functions. This is a critical step and should not be skipped.

Slowly rotate your hydraulic drive motors

Make sure that you do this on both wheels and in both directions. This will help warm up your hydro-static drive and hydraulic swing motors on the turret of manlifts. It’s very important that you do this rotation in all directions to ensure that the entire component is warmed up.

Travel slowly in forward or reverse.

This slow motion will help to warm up your transmission, drop boxes, differentials, and planetary compartments. Don’t skip this step! These important components must be warmed up, too. The act of traveling will help to heat up your oil as well as the metal components of the unit.

Gently drive the machine and work the hydraulics until reaching full speed

This will help to warm up other various metal components and the different oils within the machine. It also ensures that the seals do not undergo too much stress while being cold and will help avoid any seal failures.

You may think some of these steps are unnecessary or a waste of time. Look at it this way: the time you spend warming up your machine is downtime that you will save later due to component failure or damage. You might as well spend the time now rather than be frustrated with a broken piece of equipment later. Our top 5 winter forklift safety tips will help your equipment in more ways than one. By ensuring everything is nice and warm before you get to work, you’ll reduce oil leaks and decrease your likelihood of hose failure. Because you’re less likely experience equipment issues, you’ll get to enjoy increased uptime and productivity.

Missed a step and need some help? We’ve got your back! Accidents happen, and we get that. That’s why we are fully equipped with a variety of service options to suit your needs. Whether you need mobile service, or you can get your downed equipment to our branch, we can help. We can send one of our factory trained technicians to your site to or arrange in-shop service get you back up and running.

As promised, here is our helpful and printable graphic with our top 5 winter equipment operation tips to help you get through the months ahead! Post this in a high-traffic area of your equipment yard so everyone has this handy reminder during the winter months. This infographic also makes a great topic for safety meetings or toolbox talks to get your day started.