-

Lithium-Ion Technology - Electrify Your Warehouse & Logistics Operations!

Updated: May 17, 2023The use of electric pallet jacks has become increasingly popular in recent years due to advancements in technology and the numerous benefits they offer to warehouse and logistics operations. One of the most significant advancements in technology has been the development and use of lithium-ion batteries, which offer numerous advantages over traditional lead-acid batteries.Full story -

How to Buy an Electric Forklift

Updated: Mar 15, 2023Vendors of material handling equipment (aka – forklifts) in recent years have seen the growth of electric solutions for their customers that provide many benefits that this article will touch on. However, the solutions that providers present are not all equal.Full story -

CHOOSE WISELY - Know your applications needs

Updated: May 11, 2023It is important to fully understand the application needs before selecting a forklift because different forklifts are designed for different tasks and applications. Forklifts come in a variety of sizes, configurations, and load capacities, and selecting the wrong forklift can lead to inefficiency, safety issues, and equipment damage.Full story -

5 Ways AisleMaster can help you rethink your warehouse space

Updated: Jan 5, 2023We believe that this product is a game-changer for the warehousing industry, and we are proud to be supporting AisleMaster in their mission. The features of this machine allow for increased efficiency, productivity, and safety at a low cost of ownership. Whether your warehouse is large or small, short or tall, rectangular or L-shaped, AisleMaster can provide the ideal solution for efficiently storing goods within your facility.Full story -

High-capacity telehandler demand is reaching new heights!

Updated: May 15, 2023High-capacity telehandlers, no longer a niche market in North America. Demand is predicted to continue to rise. Industries are realizing that these versatile machines can do the job with less time and effort exerted. Read more...Full story -

Carer high-capacity Electric forklifts – Doing the heavy-lifting for over 45 years

Updated: Oct 31, 2022Carer Forklifts have been doing the heavy lifting in the electric forklift market for many years. Check out the entire product line of high-capacity electric lift trucks.Full story -

The New Green Forklift: Carer A70X

Updated: May 30, 2022Carer has been at the forefront of green forklift design and development for nearly half a century. Read more about the latest developments in green forklift technology!Full story -

Skid Steer Uses

Updated: May 10, 2022Skid steer loaders are one of the most versatile machines out there. Read more to find out the innovation history of this American equipment design!Full story -

High-Capacity Electric Shipping Container Forklifts in Seaports

Updated: Jun 13, 2022Wondering how a port terminal can transition from IC to EV material handling equipment without sacrificing power and efficiency? Read our exposé on Carer Forklifts in seaports!Full story -

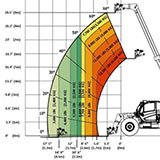

How to Read a Telehandler Load Chart

Updated: Jun 13, 2022Have you ever see a telehandler load chart and wondered what the grid and calculations mean for your real world application? Read our quick breakdown to gain new safety knowledge and boost efficiency when operating your unit!Full story -

5 Winter Forklift Safety Tips

Updated: Nov 4, 2021The cold and wet weather can cause serious equipment damage if you aren’t careful. We want to help you protect your greatest assets. That’s why we’ve put together our top 5 winter forklift safety tips to help get you through the coming months.Full story -

Knowing When to Replace Your Forklift

Updated: Dec 4, 2020To ensure your fleet isn’t hurting your budget, you need to know what each forklift’s ownership and maintenance costs are. These costs can be determined by referencing PM records, inspection reports, and your hour meter.Full story -

5 Ways to Increase the Usable Life of Your Forklift

Updated: Feb 24, 2020Regardless of the application, you want your forklift to deliver reliable performance for as long as possible. That’s why it’s important to ensure you’re using safe practices and performing regular maintenance on your machine.Full story -

Debunking 4 Electric Forklift Myths

Updated: Feb 13, 2020When it comes to electric forklifts, many operators and industry specialists have some preconceived ideas about their power and operation. This is typically due to the fact that there many myths surrounding the capabilities and limitations of electric forklifts.Full story -

The Importance of Proper & Frequent Forklift Greasing

Updated: Dec 11, 2020Did you know every manufacturer recommends a weekly forklift greasing schedule to ensure the best performance? This means that whether you’re working in warehousing, construction, or gas & oil, it is crucial that your forklift is sufficiently greased on a regular basis. Proper greasing will reduce friction and grinding between components, prolonging the life of your equipment while reducing downtime and saving you money.Full story